Create the Future

Satisfying customers is our pursuit

Enterprise development, hand in hand with you, I move forward together

Advantages of sludge-free rotary pump

Advantages of sludge-free rotary pump

1.Due to the special structure, the delivery of the medium in the sludge non-blocking cam rotor pump is relatively short, unlike the screw pump, which has a long contact line, so the particles can easily pass through. Non-2.blocking rotor pump has small structure size, small floor space, high efficiency and convenient maintenance

The non-blocking rotor pump can convey the medium in the reverse direction, and can run dry for a short time without breaking the mechanical seal

3.Linear lobe rotor pumps will have large pressure fluctuations during operation, and the use of spiral rotors can solve this problem

Selection skills of cam rotor pump

Selection skills of cam rotor pump

The lobe rotor pump is a positive displacement pump for conveying high-viscosity materials, so how do you choose a lobe pump suitable for your own material transportation?

First of all, we must understand the nature of the material, whether it is affected by temperature, such as chocolate, honey, maltose, etc... When the temperature is high, the fluidity is better, and the lower the temperature, the worse the fluidity. At this time, you can add a heat preservation system according to your needs to improve conveying efficiency.

Secondly, determine the operating speed according to the viscosity of the material. The greater the viscosity, the lower the motor speed and the corresponding decrease in flow. The lower the viscosity, the better the fluidity. The higher the motor speed, the larger the flow.

The most important thing is to determine the use flow rate, how much material you want to output per hour, and the head.

The cam rotor pump produced by Hebei Rongsheng Machinery Co., Ltd. has complete models and specifications, suitable for various working conditions, and can also be customized by calling, providing one-to-one free selection service.

Cam rotor pump transmission mode

Cam rotor pump transmission mode

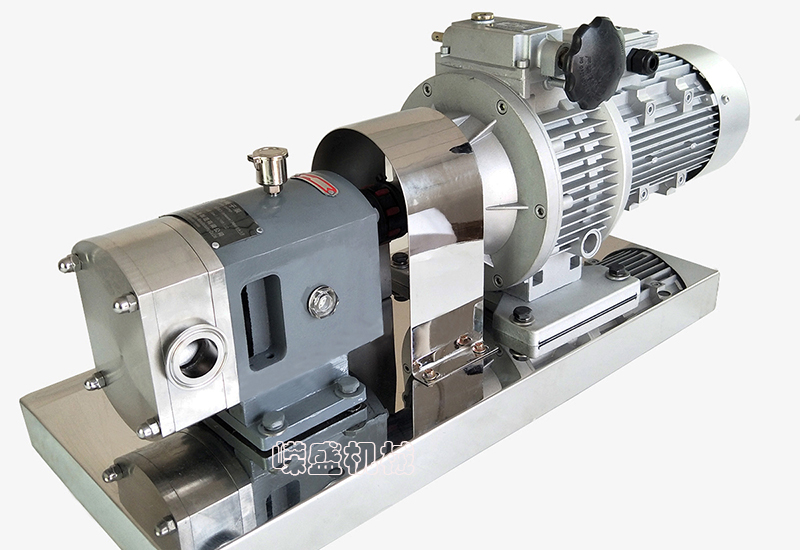

The cam rotor pump is suitable for food, medical, daily chemical, sludge, crude oil, environmental protection, fire protection, water supply and drainage and other related industries that have hygiene requirements. The rotor pump is designed to rotate two non-contact cams to convey viscous For materials, even those containing solid suspended particles, the cam rotor pump is also called a universal delivery pump, which can be configured according to the viscosity of the material. The cam rotor pump produced by Rongsheng Machinery mainly has the following transmission modes

1. Motor + stepless speed reducer

This uses a more common transmission method, which is composed of pump head + motor + handwheel speed reducer. Its characteristics are safety and reliability, large torque, and speed adjustment according to the viscosity of the material. It is suitable for chocolate, syrup, etc. Materials that are greatly affected by temperature.

2. Servo motor + reducer

The cam rotor pump is matched with a servo motor, which can realize quantitative conveying of materials, and is mostly used for filling in the food industry. This transmission mode is controlled accurately and does not lose step.

3. Motor + fixed speed ratio reducer

This kind of transmission is relatively simple, the speed is constant, and the flow is fixed and not adjustable.

The requirements of the sliding vane pump for the motor

The requirements of the sliding vane pump for the motor

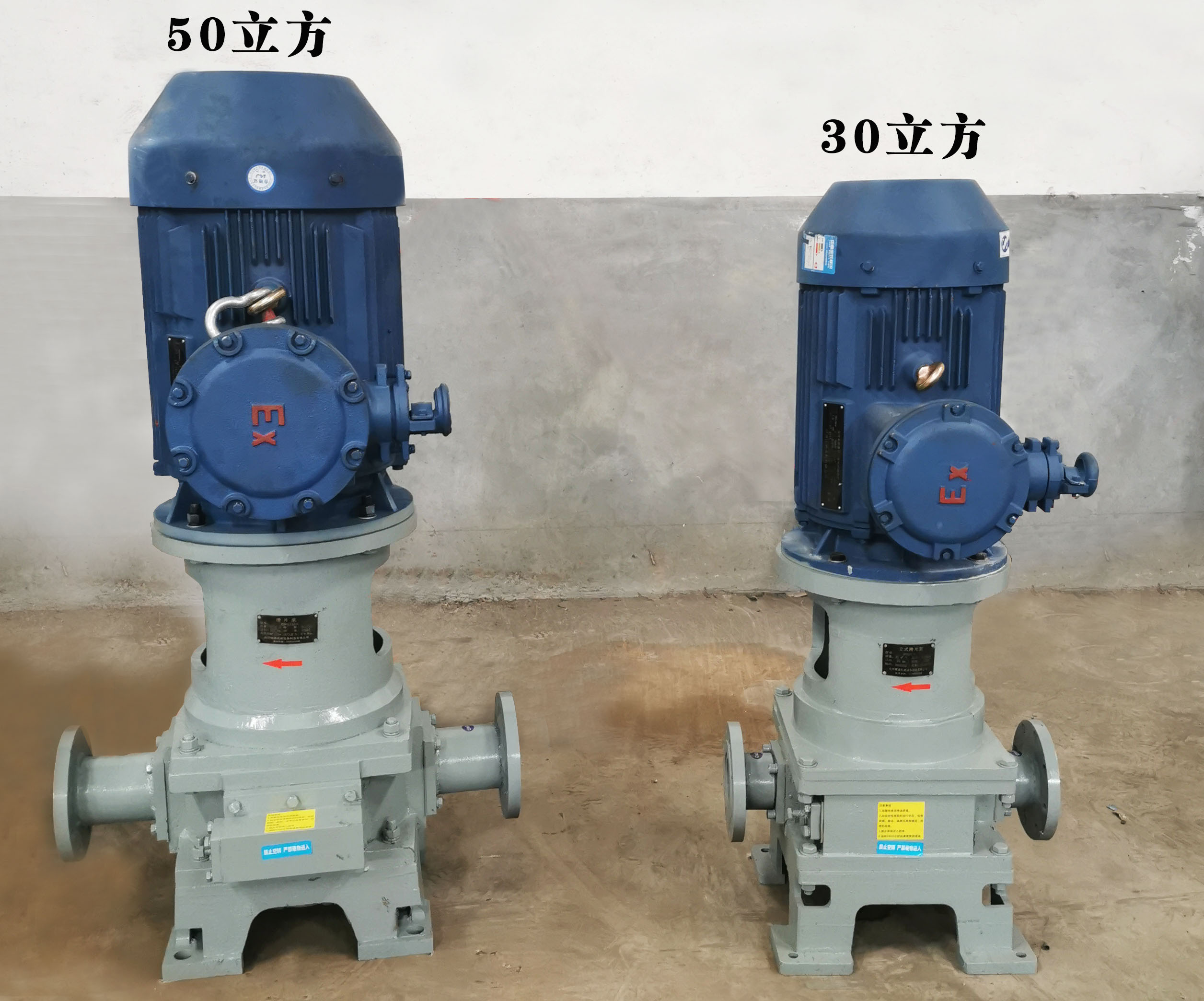

Requirements of explosion-proof sliding vane pump unit for motor

Low-voltage motors shall be high-efficiency energy-saving motors, and their efficiency shall not be lower than the level 2 energy efficiency limit specified in Energy Efficiency Limit Values and Energy Efficiency Grades of Small and Medium-sized Three-phase Asynchronous Motors (GB1861E012), and "china energy label" shall be affixed to the motors.

The protection level of junction box becomes IP55. A rain cover should be added to the motor roof installed vertically. The entrance of the main junction box of the motor adopts the direct cable entry mode, and the joint meets the explosion-proof requirements. The motor manufacturer provides the cable explosion-proof sealed clamping joint (bell mouth entry)

The motor shell shall be formed at one time with horizontal and vertical parallel cooling ribs or radiation cooling ribs to ensure good heat dissipation of the motor

According to the box should have grounding bolt, and should be near the grounding bolt with clear permanent grounding sign.

The nameplate shall be a stainless steel nameplate fixed on the stationary parts of the engine base, with standard fonts and clear marks, and shall be stamped by matte stamping process. , the installation place should be conspicuous and easy to watch

The nameplate shall indicate GB 755;; IEC 60034-1。

Operating conditions

The motor starts directly at full voltage. When the terminal voltage of the motor is not lower than 80% of the rated voltage, the motor can drive the unit to start.

The motor starts directly at full pressure, and normal starting allows cold state twice and hot state once.

When the deviation between the power supply voltage and the rated voltage does not exceed 5%, the output power of the motor should be kept at the rated value, and the insulation level is F 。

The development trend of sliding vane pump

The development trend of sliding vane pump

The sliding vane pump has good cavitation performance and self-priming ability, can operate without cavitation, eliminates environmental pollution and oil waste during the operation of the vacuum system, and especially prevents accidents. The pump has a small installation area and is convenient It can be installed in an open environment, saving civil investment and equipment costs. Because of its remarkable performance, it is safe and reliable. It has long been widely used in motor vehicle refueling in developed countries. It is also a standard pump for military and oil companies in many countries.

At present, centrifugal oil pumps are mostly used for unloading oil from domestic tank trucks. The oil is filled with pipelines by suction pipes and vacuum system devices, and enters the centralized pump room. The centrifugal pumps are added to unload the oil. This method requires pumps. The suction port can only work under negative pressure, and the cavitation phenomenon is not improved.

Although the domestic research on the sliding vane pump started late, it has made rapid progress. Through digestion and absorption of foreign advanced technology, our company designed KHB series sliding vane pumps and magnetic drive sliding vane pumps to replace centrifugal pumps, screw pumps, etc. In terms of transportation problems, this product has been widely used in military and local construction. It has very important significance and significant social benefits for simplifying the types of military and local oil pumps, improving oil supply capabilities, technical levels, economic benefits and ensuring safety. .

Sliding vane pump production

Sliding vane pump production

The production operations of the sliding vane pump cover are as follows:

1. Preparations (pump cover)

1.1 The operator should wear protective labor protection equipment.

1.2 Check the condition of lathe, milling machine and drilling machine.

1.3 Place the workpiece in a suitable area.

2. Lathe machining process

2.1 Fix the workpiece firmly

2.2 Choose suitable cutting tools and measuring tools.

2.3 Processing according to the tolerance requirements of the drawings.

3. Drilling machine processing

3.1 Clamp the turned workpiece firmly

3.2 Choose suitable drill bits and measuring tools.

3.3 Process according to the requirements of the drawings.

4. Tapping processing

4.1 Clamp the large cover with holes firmly

4.2 Choose suitable taps and measuring tools.

4.3 Processing according to the requirements of the drawings.