1 Overview

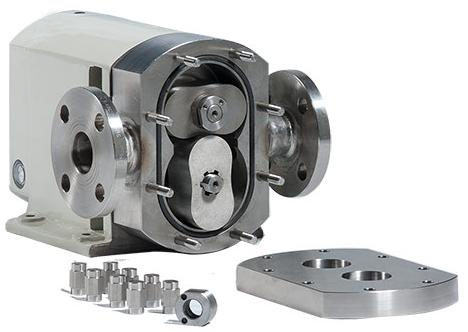

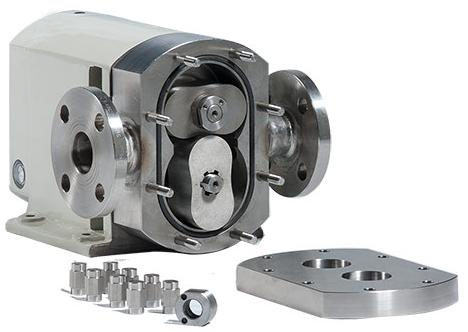

WNB cam rotor pump is a rotary positive displacement pump with high efficiency, long life, suitable for conveying temperature -30℃~180℃, viscosity 30~1.0X105cSt, suspended liquid containing solid particles and medium with high requirements for corrosiveness and hygiene. The parts inside the pump body that are in contact with the medium are made of stainless steel. It is a kind of food pump.

2. Features

Conveying high viscosity and low speed

The characteristics of high output torque and high temperature resistance make the rotor pump have outstanding performance in the field of conveying high viscosity and high temperature materials. Its unique working principle is combined with the use of a strong drive system. To ensure that the rotor pump can output a strong driving torque at low speed, it can ensure continuous and non-stop conveying of materials, and can ensure that the materials will not be damaged during the conveying process, and the conveying viscosity can be as high as 1000000CP.

304 material

All parts in contact with materials are made of stainless steel materials that meet sanitary standards, which can meet all sanitary and corrosion-resistant applications in food, beverage, medical, chemical and other industries.

Insulation design

According to different working occasions, a rotor pump with insulation jacket function can be provided. This structure ensures that the material that is easy to solidify at low temperature will maintain a constant temperature during the transportation process without condensation.

Machinery Seal

It can provide a mechanical seal structure with flushing function to prevent material from condensing on the end face of the mechanical seal during the transportation of high-viscosity materials and affect normal operation, and can ensure the service life of the mechanical seal in a dangerous environment.

Wearing parts

There is no wear of any parts of the rotor pump during work. All parts in contact with the material are made of stainless steel. A pair of rotors operate synchronously during work, maintaining a certain gap between each other, without any contact, and there will be no theoretical Any wear and tear, the rotary lobe pump can work in various environments up to 220 degrees.

3. Working principle

.jpg)

Relying on two synchronously and counter-rotating rotors (the number of teeth is 2-4) produce suction (vacuum) at the inlet during the rotation, thereby sucking in the material to be conveyed. The two rotors divide the rotor chamber into several small spaces and run in the order of a→b→c→d. When running to position a, only chamber I is filled with medium; when reaching position b, part of the medium is enclosed in chamber B; when reaching position c, chamber A is also closed with medium; when reaching position d, chambers A, B and II The chambers are connected, and the medium is delivered to the outlet. In this way, the medium (material) is continuously transported out.

4. Scope of application:

Dairy products: yogurt, fresh cream, ice cream, cheese cubes and whey.

Beverages: beer, wort, yeast, soft drinks, fruit concentrates, fruit juice drinks.

Food: tomato sauce, fruit puree, vegetable paste, pudding, jam, jelly, flavoring, fruit filling, sweetener, yeast puree, salad seasoning, batter, minced meat, minced meat, tahini, etc.

Candy: maltose syrup, cream filling, chocolate sauce.

Cosmetics: facial creams and lotions, hair gels, hair dyes, essential oils.

Medicines: pill paste, extract, emulsion, ointment.

Chemicals: fats, solvents, resins and polymers, dyes.

5. Rotor type

图一 图二 图三

Figure 1. It is suitable for conveying solid materials containing large particles. Its unique shape and curve make it more advantageous than other types of pumps when conveying large particles, and it can effectively avoid particle breakage during the conveying process.

Figure 2. Due to the use of butterfly rotors, in addition to the characteristics of general rotor pumps, it has certain advantages when transporting materials with high viscosity and larger particles, and can effectively transport particularly viscous materials .

Figure 3. The volumetric efficiency of the three-lobe rotor is relatively high, and the pulsation is small. For fluids of general viscosity, the flow rate is relatively large, the pressure is relatively high, and the application range is the widest, but it is not suitable for conveying fluids containing particles.

6. Selection parameters

| model |

flow |

Rotating speed |

power |

Outlet pressure |

Viscosity range |

Exit caliber |

| Model |

L/100r |

m³/h |

r/min |

KW |

Mpa |

cp |

mm |

| WNB1-A |

4.2 |

0-3 |

0-960 |

0.75 |

0-0.4 |

0-300000 |

19/25 |

| WNB1-A |

4.2 |

0-3 |

0-960 |

1.1 |

0-0.6 |

19/25 |

| WNB3-B |

12.5 |

0-6 |

0-960 |

1.5 |

0-0.6 |

25/32/38 |

| WNB3-B |

12.5 |

0-6 |

0-960 |

2.2 |

0-1.2 |

25/32/38 |

| WNB5-B |

20 |

0-6 |

0-500 |

3 |

0-1.2 |

50 |

| WNB7-C |

29 |

0-9 |

0-500 |

3 |

0-0.6 |

50 |

| WNB10-C |

42 |

0-13 |

0-500 |

4 |

0-1.2 |

65 |

| WNB20-D |

85 |

0-21 |

0-400 |

7.5 |

0-1.2 |

65/80 |

| WNC30-D |

125 |

0-30 |

0-400 |

11 |

0-1.2 |

80/100 |

| WNB50-E |

210 |

0-50 |

0-400 |

18.5 |

0-1.2 |

125 |

.jpg)